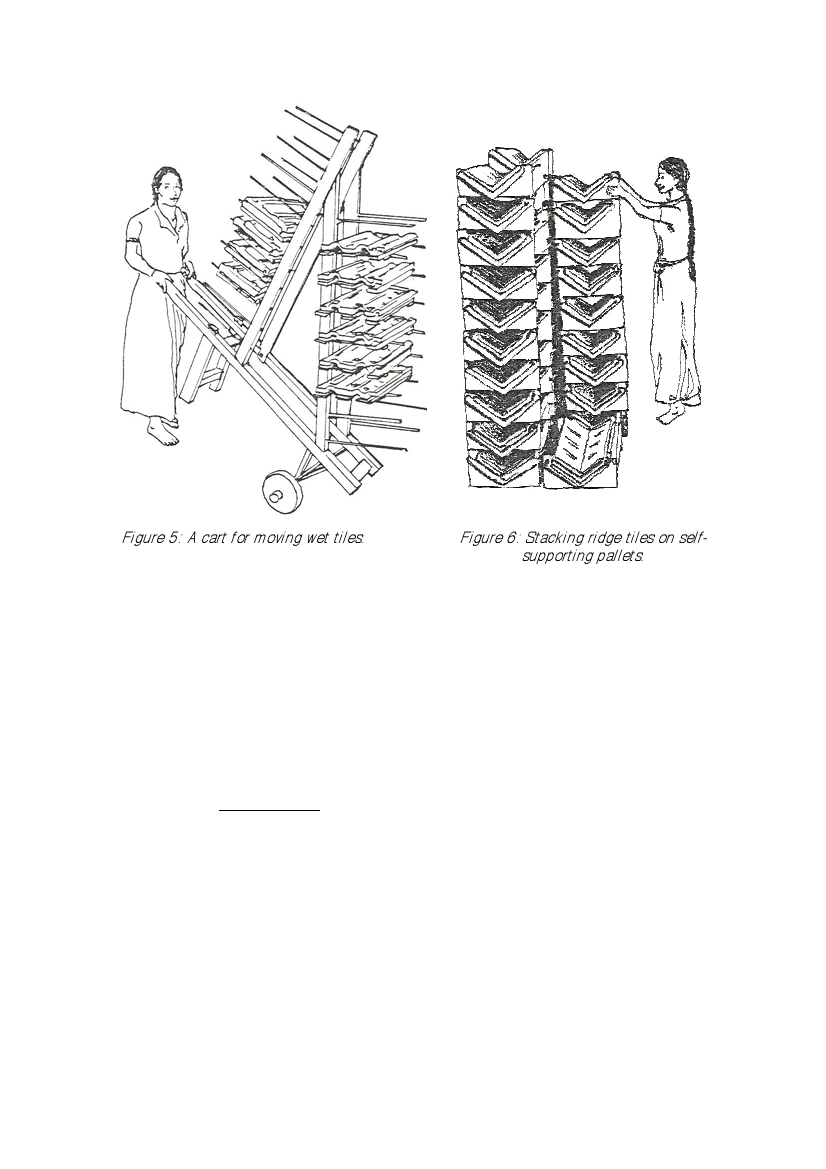

Figure 5: A cart for moving wet tiles.

Figure 6: Stacking ridge tiles on self-

supporting pallets.

2.5 KILN

The kiln fires the clay tiles into hard ceramic. Literally hundreds of kiln designs are in use

today in the heavy ceramic industry. The proper kiln must match the factory's production

rate, the product being produced, the fuel, and the experience level of local kiln builders and

operators. The kiln design which is presented here is unusually straightforward to operate,

and fits the requirements of a high output tile factory.

This kiln is of the DOWN DRAFT variety. The flames and gases from the fires enter and rise to

the top of the load in the kiln. As the gases deposit their heat to the load and cool, they filter

down to the bottom of the kiln, and are finally removed through the chequer floor. The

chequer floor is designed to support the load while allowing gases to pass through with

minimal resistance. The gases are drawn up through four tall chimneys, two on each side of

the kiln. Each chimney is provided with a damper. It is important to remember that the draft

is established by the suction of the chimneys, not the 'push' of the fire. To start the kiln, the

dampers are left completely open. Once the draft is established, the dampers are used to

regulate the draft which is kept as small as possible while maintaining adequate firing

temperatures.